Hot on the heels of sister brand KTM, Husqvarna has revealed its full 2018 enduro bike launch complete with fuel-injected 250 and 300cc two-stroke models. Our chief tester Dave Willet jetted out to Canada today and will be riding the bikes tomorrow, so watch out for lots of updates on our social media channels. Husky’s official info says:

Husqvarna has launched its complete line-up of 2018 enduro models – a sophisticated new series of 2-stroke and 4-stroke machines that take the historic brand’s enduro model line-up to a whole new level in terms of technology and performance.

Introducing the next generation of 2-stroke machines – the all-new, electronic fuel-injected TE 250i and TE 300i – Husqvarna’s latest enduro offerings deliver unprecedented advantages in terms of performance, rideability, fuel consumption and ease of use. The introduction of electronic fuel injection by Husqvarna Motorcycles represents a bold new step into the future of offroad motorcycling.

Together with the fuel-injected 2-strokes, Husqvarna Motorcycles present a heavily updated range of TE and FE machines for model year 2018. Collecting feedback from top-level competition and combining it with extensive research, the brand’s engineers ensured that the 2018 TX 125, TE 150 (only for US), FE 250, FE 350, FE 450 and FE 501 remain true to Husqvarna Motorcycles’ commitment to offer premium motorcycles across their complete enduro range.

2-STROKE’S NEW ERA

Perfectly embodying Husqvarna’s pioneering spirit, the new from the ground up electronic fuel injected TE 250i and TE 300i machines feature engine technology that revolutionises the field of 2-stroke enduro motorcycles.

TE 250I/300I ELECTRONIC FUEL INJECTION HIGHLIGHTS

=>Fuel injectors at the transfer ports → Ideal amount of fuel in all conditions

=>Oil pump & oil tank → Convenient, eliminates pre-mix

=>39 mm throttle body → Regulates air flow, TPS relays airflow data

=>New EMS → Modern engine management, no need for jetting changes

=>Standard map select → Customise power characteristics

=>Frame integrated oil filler cap → Simple refills

=>Translucent fuel tank → Large capacity, fuel pump integrated

=>New intake snorkel → Adapted to throttle body

SETTING THE BENCHMARK

Combining the most advanced engine technology with a series of dynamic upgrades, all Husqvarna Motorcycles 2-stroke and 4-stroke machines set the benchmark in terms of handling, power, weight and aesthetics.

MY18 ENDURO HIGHLIGHTS (ALL MODELS)

=>WP Xplor 48 front fork → New fork tubes & setting for added sensitivity & bottoming resistance

=>New Magura brake callipers & GSK discs → Optimal sensitivity & progression

=>New ProTaper handlebar → Class-leading function & style

The new Husqvarna MY18 enduro range will be available worldwide from July 2017 at all authorised Husqvarna Motorcycles Dealers. For all details on pricing and availability, please refer to your national Husqvarna Motorcycles Subsidiary or Importer.

The full information says:

INTRODUCTION

Enjoying over 100 years of uninterrupted manufacturing while developing some of the world’s first offroad production machines, Husqvarna are true enduro pioneers. A dominant force in international competition since the late ‘60s, Husqvarna has always been a great advocate of 2-stroke technology.

Adding to their long list of ground-breaking innovations, for model year 2018 Husqvarna Motorcycles introduce their next generation fuel-injected 2-stroke TE 250i and TE 300i machines. Together with an extended list of refinements designed to further improve the performance of all TE models, the all-new 2-strokes feature revolutionary technology in the offroad competition segment.

This pioneering electronic fuel injection system offers unprecedented advantages in terms of performance, rideability, fuel consumption and ease of use. The introduction of this new technology by Husqvarna Motorcycles is a bold new step into the future of offroad motorcycling.

Husqvarna MY18 TE 250i/300i in one sentence

Redefining 2-stroke enduro motorcycles, Husqvarna’s MY18 TE 250i and TE 300i machines feature electronic fuel injection – a revolutionary technology which represents a bold new step into the future of the offroad competition segment.

Husqvarna MY18 TE 250i/300i in 140 characters

Featuring electronic fuel injection, Husqvarna Motorcycles’ 2018 TE 250i & 300i bikes set new standards for premium enduro machinery.

Husqvarna MY18 TE 250i/300i in one short paragraph

Combining race-proven reliability with premium quality, Husqvarna Motorcycles’ 2018 TE 250i & 300i models feature electronic fuel injection – a revolution for offroad competition machines. Perfectly combining performance, controllability and ease of maintenance, the all-new 2-stroke models do away with pre-mixed fuel and the need for jetting changes. Additional benefits include reduced emissions and largely extended fuel autonomy.

Husqvarna MY18 TE 250i/300i in one paragraph

For MY18, Husqvarna Motorcycles are taking a big leap forward, introducing a revolutionary electronic fuel injection system on their TE 250i and TE 300i 2-stroke enduro models. This new technology redefines both the market and future of 2-stroke offroad competition motorcycles, cementing Husqvarna Motorcycles’ position as pioneers in the enduro sector.

Offering unprecedented advantages in terms of performance the TE 250i and TE 300i models are now even more manageable with increased control and convenience. With fuel injection bringing serious benefits in terms of added ease of use, this new technology eliminates the need for oil premix and jetting changes.

Retaining the much-loved 2-stroke character, the two new models also benefit from reduced emissions and a notably lower fuel consumption that seriously increases the bikes’ autonomy for long days on the saddle.

Combining advanced engine technologies with a series of newly-introduced, dynamic upgrades, Husqvarna Motorcycles’ engineers have ensured that the all-new TE 250i/TE 300i machines will continue setting the benchmark in terms of handling, power, weight and aesthetics.

2-STROKE ELECTRONIC FUEL INJECTION SYSTEM

Engine Management System (EMS)

The EMS features a new electronic control unit (ECU) that is responsible for a number of functions. Gathering information from the throttle position sensor, the ambient air and intake pressure sensors and the crankcase pressure and water temperature sensors, it automatically compensates for temperature and altitude changes eliminating the need to modify carburettor jetting. A standard map select switch allows riders to customise power characteristics according to personal preference or in varying conditions.

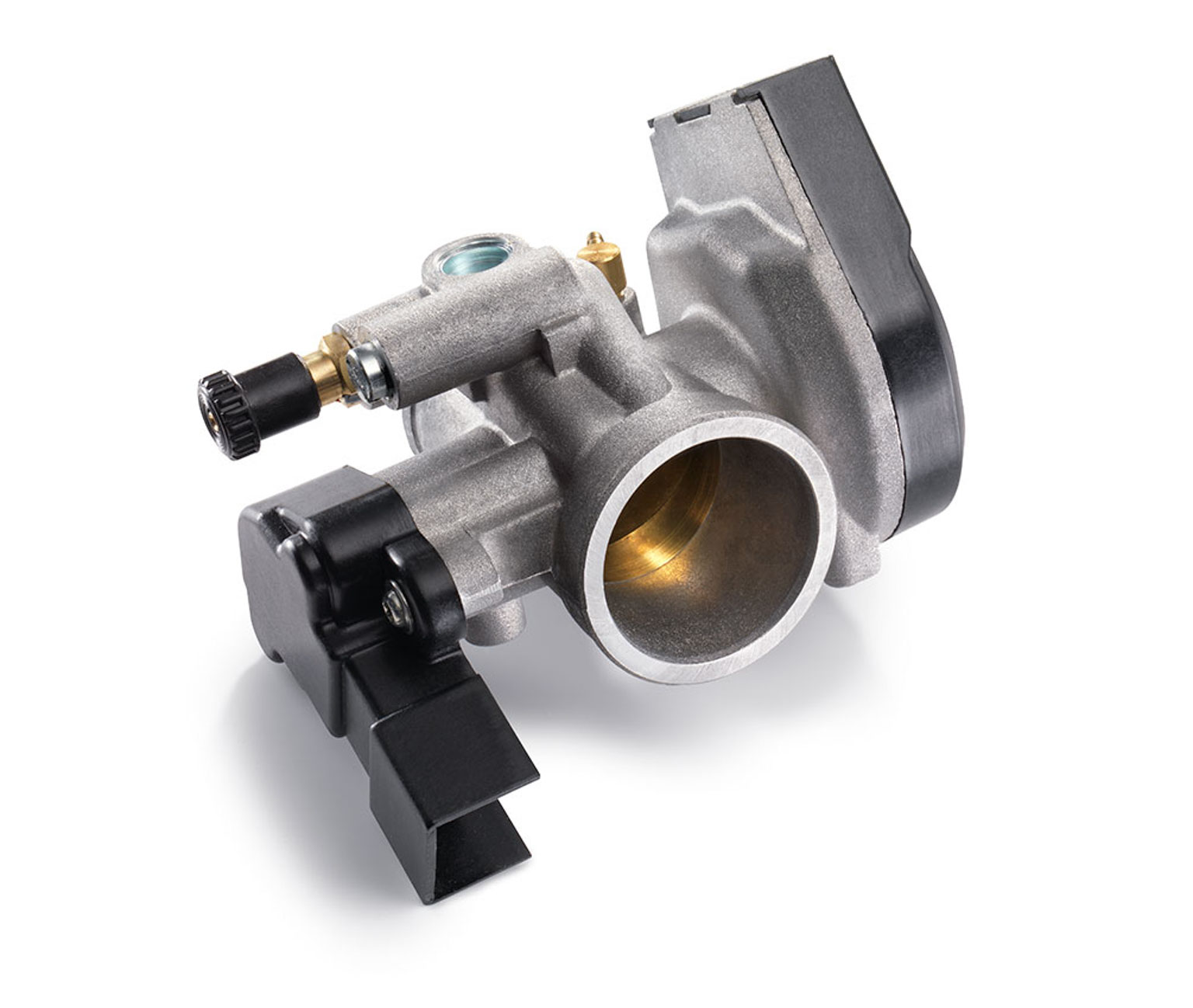

Throttle Body

Both models feature a 39 mm Dell´ Orto throttle body that is linked to the new dual cable handlebar throttle assembly. With a new throttle position sensor (TPS) relaying airflow data to the ECU, the system ensures optimal air, fuel and oil mixture. Additionally, the system features a bypass screw for idling speed regulation, with a cold start device providing more air for cold starts.

Oil Tank & Oil Pump

Vital for crankshaft, cylinder and piston lubrication, the 2-stroke oil is stored in a separate tank that together with an electronic oil pump eliminate the need for pre-mixing. With its filler tube running through the upper frame, the 0.7 litre tank contains oil for five full tanks of fuel depending on riding conditions. Controlled by the EMS, the oil pump delivers the ideal amount of oil according to the current RPM and engine load reducing waste as well as excessive smoke from the exhaust. The average ratio achieved for fuel/oil is 80:1.

Fuel Tank

The two models feature a fuel tank made of translucent plastic so the fuel level can be checked quickly and easily. The fuel tank has a 9.25 litre capacity and houses an integrated fuel pump and fuel level sensor.

2-STROKE ELECTRONIC FUEL INJECTION – HIGHLIGHTS

- Fuel injectors at the transfer ports → Ideal amount of fuel in all conditions

- Oil pump & oil tank → Convenient, eliminates pre-mix

- 39 mm throttle body → Regulates air flow, TPS relays airflow data

- New EMS → Modern engine management, no need for jetting changes

- Standard map select → Customise power characteristics

- Frame integrated oil filler cap → Simple refills

- Translucent fuel tank → Large capacity, fuel pump integrated

WHAT ELSE IS NEW IN THE 2018 ENDURO MODEL RANGE?

Ideally combining the most advanced engine technology with a series of specific chassis upgrades, Husqvarna Motorcycles’ engineers have ensured that the all-new TE 250i/300i and all other 2-stroke and 4-stroke machines will continue setting the benchmark in terms of handling, power, weight and aesthetics.

WP Xplor 48 Front Fork´s Outer Tubes and Settings

Developed by WP Performance System the front forks are specifically designed for enduro riding. They consist of an open cartridge layout with a spring in each leg and split damping functions. Compression (left) and rebound (right) can be adjusted via clickers situated on top of each tube. Fork pre-load can also be modified without the use of tools, via the standard adjuster. For MY18, the forks feature new outer tubes offering improved flex characteristics and reduced friction. A stiffer setting also provides extra sensitivity and improved bottoming resistance.

Magura Brakes

New for MY18 is the Magura front and rear braking system. Featuring a similar layout to the previous design (2 piston front & 1 piston rear), the system features optimal sensitivity and a progressive feel while delivering the highest level of performance. The diameter of the brake disks is 260mm for the front and 220mm on the rear.

ProTaper Handlebar

Second to none in terms of functionality and style, the new ProTaper handlebar features class-leading fatigue resistance while adding minimal weight. The ProTaper logos are chemically applied and are scratch and peel resistant.

Airbox

With its unique design ensuring maximum airflow and filter protection, the TE 250i/300i airbox features a new intake snorkel that is adapted to the new throttle body and holds the air temperature sensor. Air filter access remains tool-less, with the standard Twin Air filter and fail proof filter cage ensuring maximum performance and ease of maintenance.

WHAT ELSE IS NEW IN MY18 – HIGHLIGHTS

- New fork tubes & setting → Added sensitivity & bottoming resistance

- Magura brake callipers & GSK discs → Optimal sensitivity & modulation

- Pro Taper handlebar → Class-leading function & style

- New intake snorkel → Adapted to throttle body

- All listed features are valid for 2-stroke and 4-stroke models

FEATURES AND BENEFITS – CHASSIS

2–STROKE AND 4–STROKE MODELS

Frame

The hydro-formed, laser-cut and robot-welded frame is expertly crafted by WP Performance Systems. The flex characteristics are specifically tailored to benefit suspension functionality, handling and comfort. For superior protection, the frame is also fitted with frame guards and an engine protector that bolts directly to the frame.

Produced by WP Performance Systems → guarantee of high quality standards

- Tailored flex characteristics → Excellent suspension functionality, handling & comfort

- Integrated oil filler cap → Simple refills (valid only for TE 250i and TE 300i models)

Composite Carbon Fibre Subframe

Unique to Husqvarna Motorcycles, the composite subframe showcases pioneering technology and innovation. This 3-piece component is made of 30% carbon fibre, which makes it remarkably light (1.4 kg). Specific care is taken to create a calculated rigidity for optimal handling and rider ergonomics.

- 3-piece subframe → Composite materials

- Carbon fibre construction → 1.4 kg overall weight

- Specific rigidity → Perfect handling & ergonomics

Swingarm

The hollow, cast aluminium swingarm is designed to offer optimal stiffness and reliability at the minimum possible weight. The machining above the rear axle allows the chain adjuster markings to be seen from above for easy maintenance.

- Optimal stiffness and reliability in a lightweight construction

- Easy chain adjustment & maintenance

CNC-Machined Triple Clamps

The 22 mm offset black-anodised CNC machined triple clamps ensure premium quality as standard on all Husqvarna enduro models.

Expertly crafted using superior techniques and materials to provide high levels of quality and reliability. A 2-way handlebar adjustment comes as standard allowing for customisable ergonomics.

- CNC aluminium → Premium quality & reliability

- Adjustable handlebar position → Adjustable ergonomics

WP Rear Shock

The WP DCC rear shock is designed to provide advanced damping characteristics, while keeping a compact and lightweight design. With a pressure balance inside the shock the action of the stroke becomes effortless, resulting in greater rider comfort and handling. Additionally, the corrugated outer contours of the reservoir increase cooling. The component is fully adjustable and matched to a linkage system with a specific geometry to deliver the best possible traction and absorption.

- Lightweight and compact → Conforming to the lightweight & compact design

- Pressure balance → Consistent damping

- Linkage system → Specific geometry for best results

Footpeg Mount

The Husqvarna frame features a clever, self -cleaning footpeg mount that prevents the build-up of dirt collected through deep ruts or muddy terrain. As a result, the footpeg will spring back into their original position ensuring perfect control. The large aluminium footpegs have an enduro specific grip pattern. Positioned 6mm higher than on the MX models they provide increased ground clearance.

- Footpeg mount → Prevents mud & dirt build-up

- Large footpegs → Perfect grip & control with enduro specific pattern

Magura Hydraulic Clutch

The reliable, high quality, German-made clutch system guarantees even wear, near maintenance-free operation and perfect action in every condition.

Clutch play is constantly compensated so that the pressure point and function of the clutch remains identical in cold and hot conditions, as well as over time.

- Magura hydraulic clutch → Perfect action in every condition

- High quality German craftsmanship → Very reliable & consistent clutch action

ODI Grips & Throttle Assembly

The ODI lock-on grip on the left side does not require gluing, while on the right, the vulcanised grip features an integrated throttle mechanism. The assembly has easy free-play adjustment and by changing the throttle cam, throttle progression can be tailored to rider preferences.

- Throttle assembly & ODI grips → Easy grip mounting without glue

Exhaust System

The exhaust systems are expertly designed to deliver the best possible performance while adhering to strict FIM noise limits. The mufflers are crafted from lightweight and strong aluminium to reduce weight and are positioned closely to the centre of gravity to improve handling. The header pipes are specifically designed to match specific engine characteristics, delivering top level performance while keeping weight to a minimum.

- Exhausts → Mass-centralisation, light-weight, optimal performance

Electric Start & Li-Ion Battery

The 2018 Husqvarna Enduro model range (except TX 125 model) feature a standard electric starter. The system uses a compact Li-Ion battery which is 1 kg lighter than a conventional battery.

- Li-Ion battery → 1 kg lighter than a conventional battery

Integrated Cooling System

The radiators are expertly crafted by WP Performance Systems using high strength aluminium. CFD (computational fluid dynamics) is used to channel air through the radiators efficiently and provide optimal cooling in all conditions. The cooling system is integrated into the frame increasing heat dissipation while eliminating the need for additional hoses. Protecting against debris the radiator protectors also act as a brace diverting energy from an impact around the radiator and into the frame.

- Integrated cooling → Maximum efficiency in minimum space

- Radiator protectors → Protection from debris & falls

Wheels

Black high-strength alloy rims by D.I.D are coupled to CNC-machined hubs using lightweight spokes and silver anodised aluminium nipples.

- Lightweight but strong & reliable construction → Minimum unsprung weight

Tyres

Husqvarna Motorcycles’ enduro range features Metzeler 6 Days Extreme tyres. The FIM approved tyres provide advanced grip in a wide variety of conditions.

- Metzeler 6 Days Extreme tyres → Advanced grip in all conditions

Bodywork

Distinctive and futuristic bodywork, with striking pearl blue and electric yellow graphics stylishly adorn the Swedish inspired design. The advanced ergonomics provide superior comfort and control allowing riders to perform at their peak for extended periods of time.

- Bodywork → Distinctive looks, modern colours & graphics

- Advanced ergonomics → Confidence-inspiring riding position.

FEATURES AND BENEFITS – ENGINES – 2-STROKE

TE 250i/TE 300i

Engine

The 250cc and 300cc 2-stroke engines set the benchmark for unrivalled power and lightweight construction. The engines feature precisely positioned shaft arrangements for optimal mass centralisation, a counter balancer shaft to reduce vibrations, a twin-valve controlled power valve and a 6-speed enduro gearbox.

Cylinder

For MY18 two inlet positions are located on the transfer ports at the rear of the cylinder where a pair fuel injectors are mounted. The injectors deliver the fuel downwards into the transfer ports, which guarantees excellent atomisation with the air travelling upward to the combustion chamber. This ensures a more efficient burn of the air/fuel mixture resulting in reduced fuel consumption and emissions.

The 66.4mm (TE 250i) and 72mm (TE 300i) bore cylinders feature twin valve controlled power valve systems, which deliver smooth and controlled power throughout the RPM range. For different conditions and rider preference, alterations to the power delivery can be made by simply changing between the three supplied springs.

Piston

The lightweight piston is perfectly matched to each cylinder transmitting minimal oscillating mass and ensuring high levels of reliability and performance.

- Piston → High reliability and performance

Engine Casings

Both engines are designed to improve mass centralisation. As a result, the lightweight, die-cast engine casings are developed to accommodate the shaft arrangements in the ideal position, centralising oscillating mass and improving ride-ability.

Additionally, the counter balancer shafts are integrated in a very compact manner having little effect on the overall design.

- Engine casings → Mass centralisation, improved rideability

Counter Balancer Shaft

The engines house a laterally mounted counter balancer shaft. The balancer significantly reduces vibration resulting in a smoother and more comfortable ride.

- Counter balancer shaft → Significantly reduced vibration

Crankshaft

The crankshafts feature a 72 mm stroke and are balanced in conjunction with the counter balancer shaft for minimum vibration. By incorporating a heavier ignition rotor, the crankshafts produce more inertia than on the TC 250 MX model, which improves control in the lower RPM range.

Gearbox

A 6-speed gearbox features enduro specific ratios with an innovative shift lever reducing dirt build up and guaranteeing easy operation in all conditions.

- 6-speed gearbox → Enduro specific ratios

Clutch

The TE 250i and TE 300i feature a DDS (damped diaphragm steel) clutch. The clutch uses a single diaphragm spring instead of the more common coil spring design, resulting in a much lighter clutch action. This design also incorporates a damping system that increases both traction and durability. Assisted by the Magura hydraulic clutch, the system provides a light and modular feeling, which is almost maintenance and adjustment free.

- DDS clutch → Light action with integrated damping system, perfect traction & reliability

- Magura hydraulic system → Light & modular clutch action, almost maintenance free

Starter

Both models are fitted with an electric starter located below the engine ensuring the system remains well protected. Additionally, the system is linked to a lightweight and powerful Li-Ion battery for reliable starting.

- Starter motor → Located beneath the engine

- Li-Ion battery → Lightweight & reliable

Benefits

- State of the art 2-stroke technology with electronic fuel injection

- Reduced fuel consumption

- No premix needed

- Smooth & clean power delivery

- Low maintenance costs

- Hydraulic clutch

- Excellent handling & agility

TX 125/TE 150 USA

Engine

The TX 125 and TE 150 USA engines have an advanced construction featuring the latest in 2-stroke technology. As a result, both engines are powerful, light and very compact. Additionally, the engines are designed to centralise mass, providing outstanding ride-ability and minimal rider fatigue.

- Advanced 2-stroke → powerful, light and compact

- Mass-centralisation → significant benefits in handling and manoeuvrability

Cylinder and piston

The cylinder features a 54 mm bore (58 mm bore for the TE 150 USA) with an innovative power valve design that delivers class leading power and torque. The piston is designed to perfectly match the cylinder layout offering premium reliability.

- Cylinder → innovative power valve design delivering class leading performance

Crankshaft

With both models featuring 54.5 mm of stroke, the crankshaft is perfectly balanced and delivers more inertia compared to the TC 125 design thanks to a heavier ignition rotor which provides more controllable low end power.

- Lightweight crankshaft → very little vibration

Crankcases

High-pressure die cast production processes result in a thin wall thickness and a low overall weight for both engines. The shaft arrangements are located in the ideal position reducing the effect of oscillating mass for more precise handling. The historical Husqvarna logo adorns the bronze finished crankcase covers.

- High pressure die cast production process → thin walls resulting in light weight, while maintaining strength

- Shaft arrangement → mass centralization, precise handling

Starter

The design of the TX 125 engine allows for the optional fitment of an electric starter. The starter will be available in a Husqvarna accessories kit and include all the necessary equipment needed to make the modification. As for the TE 150, the model comes with both kick and electric starter as standard. The weight of the system is kept to a minimum using a lightweight Li-Ion battery which is 1kg lighter than a conventional battery of the same size.

Carburettor

The TX 125 and TE 150 feature a 38 mm flat slide Mikuni TMX carburettor. With an updated setting for MY18, the carburettor provides a smooth and controllable power delivery with optimal performance over the entire RPM range.

- 38 mm Mikuni carburettor → smooth & controllable power delivery with updated setting

Gearbox

Both models are fitted with a 6-speed wide range gearbox. The enduro specific ratios are tailored to the exact power characteristics of the two machines, while an innovative gear level reduces dirt build up ensuring perfect operation in all conditions.

- 6-speed gearbox → specific enduro gearing

- Gear lever → prevents dirt build up ensuring precise control

Magura clutch

The reliable, high quality, German-made clutch system guarantees even wear, near maintenance-free operation and perfect modulation in every condition. Meaning that play is constantly compensated so that the pressure point and function of the clutch remain identical in cold or hot conditions, as well as over time.

- Magura hydraulic clutch → perfect modulation in every condition

- High quality German craftsmanship → very reliable, consistent clutch action

Benefits

- Continuous 2-stroke development offering maximum performance & low running costs

- Low weight & agile handling

- Hydraulic clutch

- High quality standard components

FEATURES AND BENEFITS – ENGINES – 4-STROKE

FE 250/FE 350

Engine

The engines featured in both models are second to none in terms of their overall performance and versatility. All their major components and shaft arrangements have been carefully positioned to suit the performance and handling characteristics of each model. Weighing just 27.6 kg, the FE 250 engine has a quite torquey nature that makes the bike accessible for both professionals and amateurs. As for the FE 350 engine, it delivers a significant boost of power and torque offering 450-rivalling power.

- Performance, weight, mass centralisation → excellent ride-ability

- Powerful FE 250 engine → accessible for all skill levels

- Lightweight FE 350 engine → 450 rivalling power-to-weight ratio

Map Switch & Traction Control

The Husqvarna Enduro 4-stroke model range features a standard mounted handlebar map switch and an advanced traction control feature. The system is able to analyse the throttle input from the rider and the rate at which RPM increases in the engine. If the RPM increases too fast, the ECU will register a loss of grip and reduce the amount of power to the rear wheel to ensure maximum traction in all conditions.

- Traction control system for maximum traction and control

- Standard map switch for adjustable engine characteristics

Cylinder head

The DOHC design features polished camshafts with DLC coated finger followers transmitting minimal friction and improving overall performance. Added to the design are lightweight titanium valves (32.5 mm intake & 26.5 mm exhaust for the FE 250, 36.3 mm intake & 29.1 mm exhaust for the FE 350).

- Lightweight titanium valves → maximum performance

- Polished camshafts, finger followers with DLC coating → minimal friction

Cylinder and piston

The cylinder features a lightweight forged bridged-box-type piston by CP. As a result, the low oscillating masses deliver exceptional power, high revs and a very wide power band. The compression ratio is 12.8:1 for the FE 250 and 12.3:1 for the FE 350.

- Lightweight diameter piston → reduces oscillating masses

- Forged bridged-box-type piston → high performance and reliability

Crankshaft

The plain big end bearing features two force-fitted bearing shells ensuring maximum reliability and durability, guaranteeing long service intervals of 135 hours.

- Plain big end bearing with force-fitted bearing shells → 135-hour service interval

Counter balancer shaft

In order to counteract the rotational force of the crankshaft and reduce vibration, both engines use multifunctional counter balancer shafts that also drive the water pumps and timing chains.

- Multifunctional counter balancer shaft → reduced vibrations, compact design

Crankcases

Both engines are designed to be compact while centralising rotating masses. As a result, the crankcases are engineered to house the shaft arrangements at the ideal centre of gravity. The casings are manufactured using a high-pressure die cast production process, resulting in thin wall thickness while retaining exceptional reliability. The iconic Husqvarna logo adorns the bronze finished crankcase covers.

- Crankcases → light and compact, mass-centralisation

- High pressure die cast production process → thin walls for reduced weight, while maintaining strength

Gearbox

Both models feature a 6-speed gearbox with specific wide-range enduro type gearing. The shifting fork uses a special low friction coating to ensure smooth and precise shifting while a gear sensor allows the EMS to select a specific engine map for each gear. Additionally, a no-dirt gear lever prevents dirt build up allowing the mechanism to spring back into place and guarantee perfect control in all conditions.

- 6-speed gearbox → enduro specific ratios

- Integrated gear sensor → specific engine maps for each gear

DDS clutch

The two engines feature DDS (Dampened Diaphragm Steel) clutches. The exclusive characteristics of this system include a single diaphragm steel pressure plate instead of traditional coil springs making the clutch pull very light while the integrated damping system improves traction and durability. The clutch basket is a single-piece CNC machined steel component that allows the use of thin steel liners and contributes to the compact design of the engine. The Magura hydraulic system ensures perfect modulation in all conditions.

- DDS clutch → compact with optimal modulation and durability

- Magura hydraulic system → perfect clutch modulation

Benefits

- Class leading performance & weight for the FE 250

- 450 performance & 250 manoeuvrability for the FE 350

- Standard map switch & traction control

- Magura hydraulic clutch for consistent, maintenance-free operation

FE 450/FE 501

Engine

Combining low weight with a compact design, the FE 450 and FE 501 engines feature the latest technology available offering unequalled performance, ride-ability and reliability. Additionally, both engines are suited specifically for enduro type riding with a standard electric start, 6 speed wide ratio gearbox and an array of electronic rider aids.

- Updated engines → lightweight, compact & powerful

- Class leading electronics → traction control, map select, Keihin EFI

Map Switch & Traction Control

The Husqvarna Enduro 4-stroke model range features a standard mounted handlebar map switch and an advanced traction control feature. The system is able to analyse the throttle input from the rider and the rate at which RPM increases in the engine. If the RPM increases too fast, the ECU will register a loss of grip and reduce the amount of power to the rear wheel to ensure maximum traction in all conditions.

- Traction control system for maximum traction and control

- Standard map switch for adjustable engine characteristics

Cylinder head

The compact SOHC cylinder head on both engines offers maximum performance at the minimum possible weight. The camshaft actuates four lightweight valves (titanium intake Ø=40 mm 32,6 g, steel exhaust Ø=33 mm 42,6 g) through a robust rocker arm system.

- SOHC → compact engine design

Cylinder and piston

The lightweight aluminium cylinder features a 95 mm bore housing a lightweight Konig bridge-box-type piston. This combination produces very little oscillating mass significantly reducing vibration and increasing rider comfort. The compression ratio is 11.8:1 for both models.

- Lightweight aluminium cylinder → 95 mm bore

- Lightweight forged bridged-box-type piston → high performance, reduced oscillating masses

Crankshaft

A plain big end bearing comprising of two force-fitted bearing shells ensure maximum reliability and durability, guaranteeing long service intervals of 135 hours.

- Plain big end bearing & force-fitted bearing shells → increased durability & service intervals

Counter balancer shaft

In order to counteract the rotational force of the crankshaft and reduce vibration, both engines use multifunctional counter balancer shafts that also drive the water pumps.

- Multifunctional counter balancer shaft → reduced vibrations, compact design

Crankcases

The crankcases are designed to house the shaft arrangements and internals of the engine in the best possible position, centralising masses for a lightweight handling feel. High-pressure die cast production processes result in a thin but reliable wall thickness and keep weight to a minimum.

- Design → mass-centralisation, lightweight handling

- High pressure die cast production process → thin walls for reduced weight, while maintaining strength

Gearbox

The lightweight 6-speed gearboxes ensure smooth and precise shifting thanks to a low friction coating on the shifting fork. The gear lever features a design that prevents dirt build-up and keeps the lever tip in its original position even in the toughest conditions while a gear sensor allows for specific engine maps in each gear.

- 6-speed gearbox → Lightweight

- Fork coating → smooth and precise shifting

- Gear sensor → specific engine maps for each gear

DDS clutch

Both engines feature DDS (Dampened Diaphragm Steel) clutches. The exclusive characteristics of this system include a single diaphragm steel pressure plate instead of traditional coil springs making the clutch pull very light while the integrated damping system guarantees optimal traction and durability. The clutch baskets are single-piece CNC machined steel components that allow the use of thin steel liners and contribute to the compact design of the engines. The Magura hydraulic systems ensure perfect modulation in all conditions.

- DDS clutch → compact with better modulation and maximum durability

- Magura hydraulic system → perfect clutch modulation

Benefits

- Class leading performance and reliability for the FE 450

- Most powerful Husqvarna enduro engine for the FE 501

- Intuitive & confidence-inspiring riding experience

- Advanced electronics include traction control & adjustable engine maps

- Exclusive DDS clutches with Magura hydraulics for smooth & light clutch action

- Electric starters & compact Li-Ion batteries